RELIABLE ENGINES FOR CONSTRUCTION EQUIPMENT

AND INDUSTRIAL APPLICATIONS

MTU offers an array of high-performance, economical diesel engines for construction equipment, deployment in ports, or for airport vehicles and ground equipment. Moreover, our engines have also proven themselves as drive systems for stationary applications and machines such as pumps and compressors.

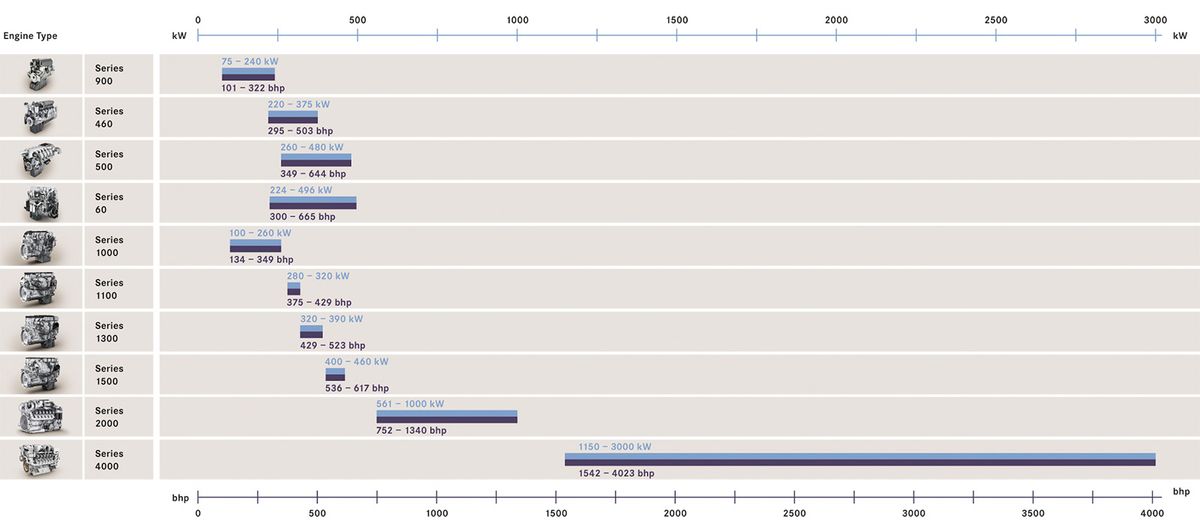

Whether wheel loaders, haul trucks or roadbuilding equipment, mobile cranes, aircraft tractors, or container cranes, our wide range of engines, with outputs of 75 kW (Series 900) to 3,000 kW (Series 4000), MTU always has the perfect engine for your equipment. As a systems supplier, MTU’s integration expertise can provide you with a complete package that is optimally tailored to your needs – with both software and hardware. Various power take-off options for highly specialized applications offer even greater flexibility.

In order for our diesel drive systems to operate trouble-free even under extreme conditions, we test them again and again in continuous operation and with full loads in the heat, cold, and dust, as well as with frequent load changes. This ensures that our engines offer maximum availability.

In addition to their well-known longevity, low-maintenance construction and long service intervals also ensure their cost-effectiveness. They minimize expenses and downtime and ensure that all equipment is fully operational again in record time.

Then there’s the efficient fuel consumption of all MTU engines, which are among the lowest-consumption engines on the market due to their second-generation common rail injection system and intelligent engine management. Optimized, efficient combustion and exhaust aftertreatment processes like SCR and cooled exhaust gas recirculation (EGR) mean that our diesel drives meet the widest range of emissions specifications up to EU Stage IV and EPA Tier 4 final.

You can also depend on MTU with regard to service: as a global partner, we will support you around the world with maintenance and spare parts – whenever and wherever you want.

THE BENEFITS:

OUR ENGINE PROGRAM:

SERIES 1000

YOUR BENEFITS:

SERIES 1100

YOUR BENEFITS:

SERIES 1300

YOUR BENEFITS:

SERIES 1500

YOUR BENEFITS:

SERIES 2000

YOUR BENEFITS:

SERIES 4000

YOUR BENEFITS:

BROCHURES/ FLYERS / SALES PROGRAMM:

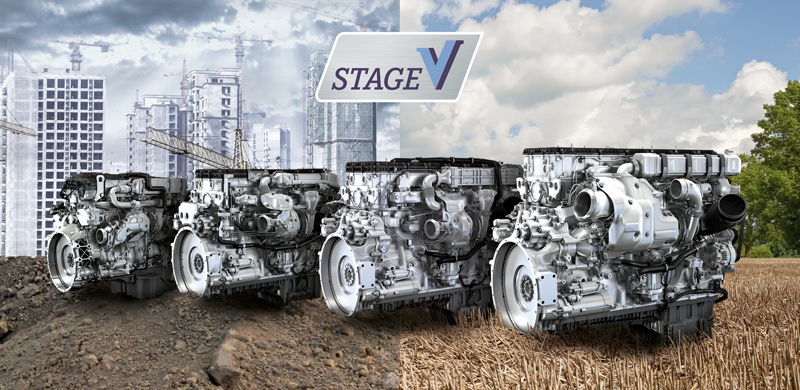

SPECIAL: STAGE V

MTU DRIVE SOLUTIONS FOR CONSTRUCTION EQUIPMENT

AND INDUSTRIAL APPLICATIONS:

MOBILE CRANES

Our engines bring truck-mounted cranes to the relevant site quickly and reliably and enable them to ascend effortlessly. Even on terrain, MTU diesel engines for crane trucks ensure safe maneuverability and high mobility thanks to their high torque even at low RPMs.

HAUL TRUCKS

MTU diesel engines provide the extremely high horsepower that haul trucks, dump trucks, and tractors need to work their way through rough terrain and hard ground. For all of that power, economic efficiency is not forgotten: MTU engines offer low specific consumption for minimal expense per ton moved.

WHEEL LOADERS, BULLDOZERS, AND EXCAVATORS

Frequent load changes and full speed with full loads: our diesel engines for wheel loaders, bulldozers, and excavators are distinguished by their optimal load response and ample power reserves for quick load cycles. Top performance, including in operating costs – are thanks to low consumption and long maintenance intervals.

ROADBUILDING MACHINES

Die nahezu unverwüstliche Technik unserer Dieselmotoren für Straßenbaumaschinen geht auch bei hohen Umgebungstemperaturen und häufiger Volllast im Mehrschichtbetrieb zuverlässig zu Werk. Durch unterschiedliche Zubehörkomponenten lassen sich die Motoren von MTU ideal an jeden Einsatzzweck anpassen.

PORT EQUIPMENT

In ports around the world, MTU engines ensure that goods are moved quickly and safely. And they don’t just power vehicles like container carrier trucks, SGVs, and reach stackers. They also drive winches and rotating and luffing mechanisms in dockside and gantry cranes.

AIRPORT VEHICLES AND GROUND EQUIPMENT

MTU’s high-performance engines drive airport ground support equipment like pushback towing vehicles and airport fire trucks. But they also power smaller ground equipment like ground power supply units, luggage transport vehicles, and runway cleaning vehicles – always individually adjusted to the requirements of the specific application.

SPECIAL AND PUBLIC UTILITY VEHICLES

With MTU’s efficient, high-performance diesel engines, special-purpose vehicle drives can be optimally adjusted to meet extraordinary demands – regardless of whether that means grooming ski slopes, clearing snow, or keeping streets clean.

PUMPS, COMPRESSORS, ETC.

Low life-cycle costs due to long maintenance intervals and low specific consumption: MTU diesel engines have also proven themselves driving pumps and compressors for generating compressed air, as well as for shredder equipment, screener crushers, trenchers, earth augers, and many other special applications.